STRUT HANDLING TOOL

Revolutionise Heavy Equipment Maintenance

with the Strut Handling Tool

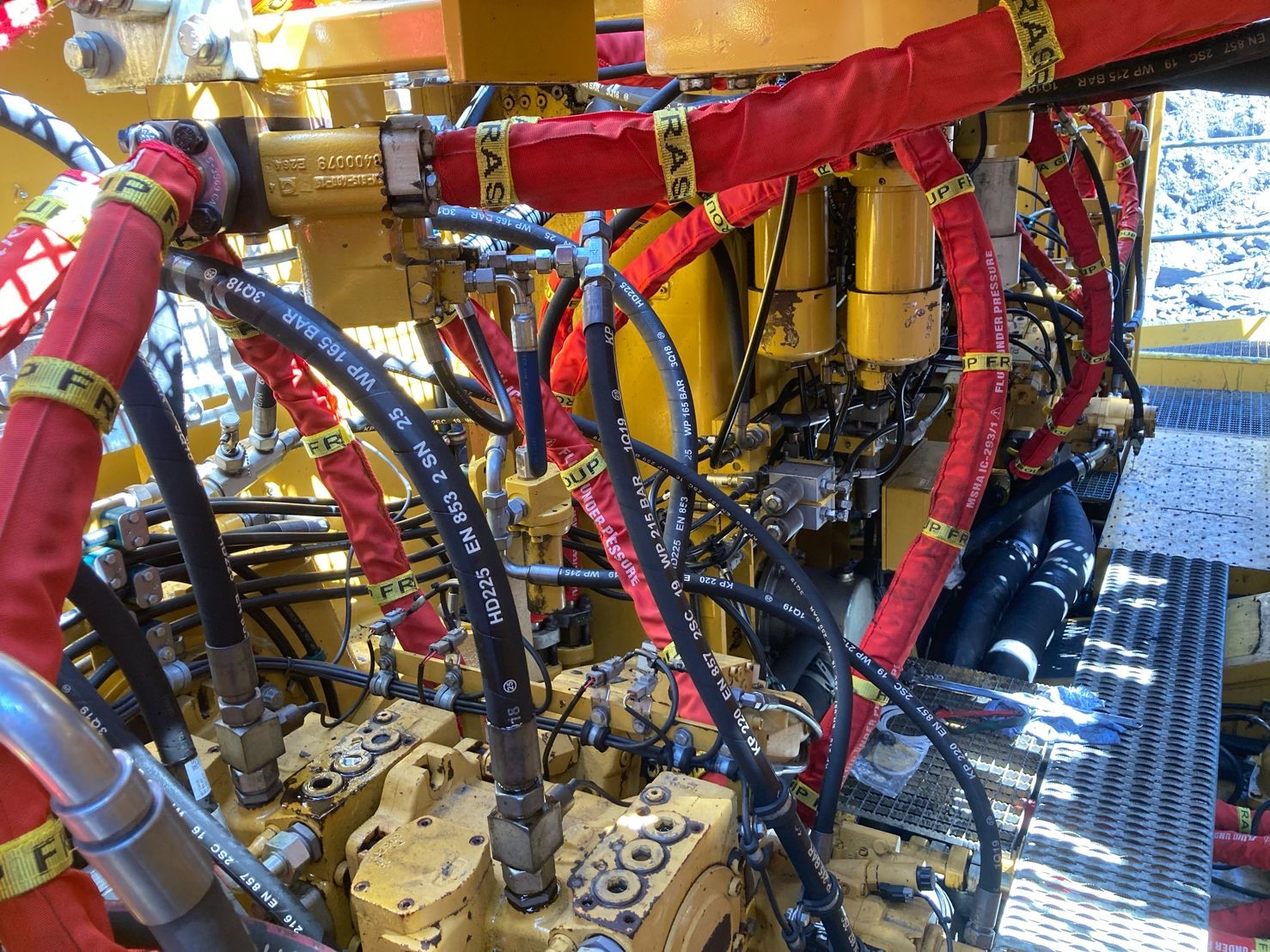

The HNA Group's Strut Handling Tool represents a significant advancement in the process of replacing front strut assemblies on Caterpillar haul trucks. Designed and assembled in Mackay, Queensland, Australia, this innovative tool simplifies the component change-out process by utilising a 16T forklift and the Strut Handling Tool, eliminating the need for overhead cranes and complex lift plans.

Manufactured with locally sourced components, the tool is designed for ease of use and enhanced safety: simply attach it to the strut assembly, remove the entire unit from the chassis, and use the remote control to safely lower the strut to a horizontal position.

For installation, the assembly is raised back into a vertical position, and the remote control allows precise rotation to align the keyway and position the assembly back onto the chassis.

Key Features

Simplified Operations

Replace Caterpillar haul truck strut assemblies without overhead cranes or complex lift plans. Faster maintenance, minimises heavy mobile equipment (HME) downtime.

Compatibility

Designed for Caterpillar Haul Truck front strut assemblies, including models 777, 785, 789, and 793. Secure attachment ensures stability during lifting.

Advanced Technology

Remote-controlled, 24Vdc battery-over-hydraulic system for precise handling. Solar charging capability giving an eco-friendly power option for continuous operation. 4-Way Movement ensuing accurate and flexible positioning of strut assemblies.

High Load Capacity

Supports up to 8000kg with precision handling.

BHP Management of Change

Approved Tooling

BHP Management of Change Approved Tooling. BHP's Management of Change (M.O.C.) includes how to identify, evaluate, approve, document, communicate, and monitor changes.

HNA Group Pty. Ltd. © 2025, ABN: 59 644 632 440

Website by Beetle Digital