ABOUT US

Revolutionising Mine Site Safety Through Engineering Innovation

Born in the Bowen Basin, HNA Group Pty Ltd was founded with a simple but powerful goal: to make high-risk maintenance work on mine sites safer and more efficient

As diesel fitters on the tools, co-founders Anthony Lye and Craig Hall saw first hand the dangers involved in hydraulic systems and heavy machinery.

Their response? To innovate practical, fit-for-purpose solutions that protect workers and optimise operations.

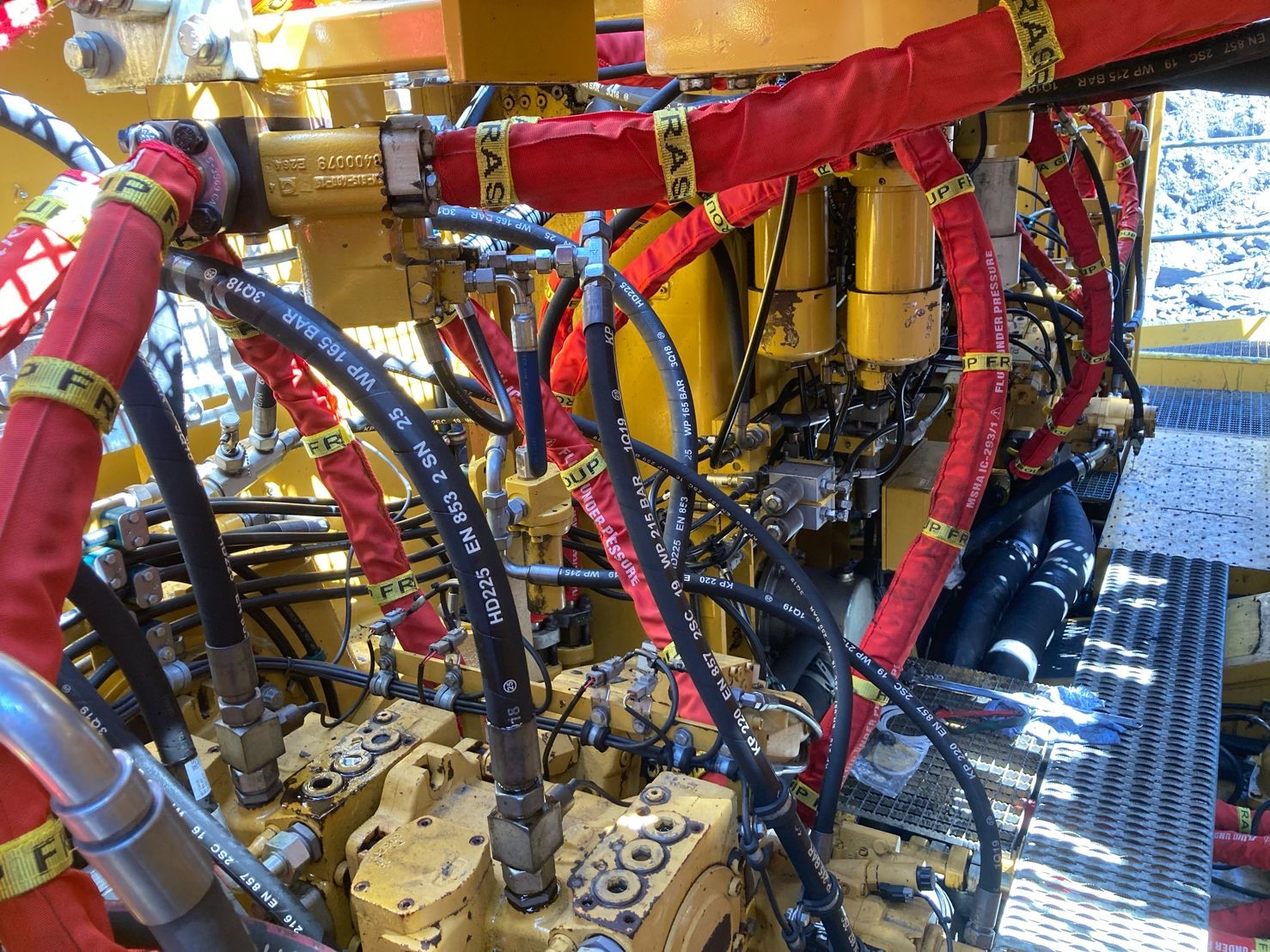

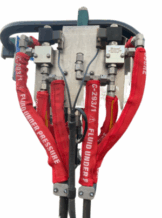

Purpose-Built for Protection

HNA Group designs and manufactures custom safety tooling and hydraulic protection systems. Our early breakthroughs include:

- HNA Band Cover

- Hydraulic Tool Sock

- Hydraulic Cylinder Covers

These tools were created to reduce the risk of high-pressure hydraulic fluid injection injuries a serious hazard with tools operating between 5,000 to 9,000 PSI.

Developed from real field experience, our solutions are used on major mining sites across Australia, including those operated by BHP, Rio Tinto, Liebherr, Thiess, MacKellar, and Coxons Group.

Engineering Evolution

From our first three tools, we’ve evolved to develop over 200+ burst sleeve kits. These are RS23 and MDG41 compliant, tailored to match high-risk hydraulic circuits with part-number-specific sleeves and installation diagrams.

We also moved into eliminating live work tooling through initiatives like Project Tutus by BHP and built custom tools that removed the need for live work tasks entirely across Queensland mine sites.

Mission & Values

Our Mission

To protect those working in high-risk environments by designing and supplying safe, simple and compliant tooling solutions.

Our Core Values

- Simple: Tools must be practical and easy to use in the field.

- Safe: Every innovation starts with protecting people.

- Compliant: We meet and exceed RS23 and MDG41 guidelines to ensure zero compromise.

Safety is our benchmark.

Whether it's shielding workers from hydraulic fluid injection or removing live work exposure altogether, every product we create reflects our absolute commitment to safe work environments.

Redefining Strut Handling

One of our proudest engineering achievements is the upgraded Strut Handling Tool, designed in collaboration with BHP. The original tool didn’t meet mine site safety expectations—so we rebuilt it from the ground up.

Key upgrades include:

- A safer 24V battery-over-hydraulic system

- Remote-control operation

- Hydraulic-driven strut rotation

- Safety features like guarding, signage, and a solar charging system

This tool is now used to change front strut assemblies on CAT haul trucks (777, 785, 789, and 793), saving around six hours per changeout while eliminating dual lifts and complex lift plans.

The Road Ahead

Our reputation has grown organically across the mining community due to the quality, simplicity, and practical value of our solutions. And we're just getting started.

Looking ahead, we’re converting select tools from air and three-phase operation to our compact 24VDC battery-over-hydraulic platform, making our tools even more portable, efficient, and safer for harsh environments.

BHP Management of Change

Approved Tooling

BHP Management of Change Approved Tooling. BHP's Management of Change (M.O.C.) includes how to identify, evaluate, approve, document, communicate, and monitor changes.

HNA Group Pty. Ltd. © 2025, ABN: 59 644 632 440

Website by Beetle Digital